R&D

We contribute to promoting human health.

We are the global leader in stem cell therapies

What is GMP Center? Good manufacturing practices (GMP) are quality control standards required by licensed agencies for the manufacture and sale of food, pharmaceuticals, cosmetics and medical devices, etc. It provides the minimum standards necessary to maintain a consistent quality level in manufacturing. The company has facilities suitable for GMP and is capable of cultivating 6000 lots per year.

GMP Center History

Possesses original technology of separate culture of fat stem cells Established more than 100 cooperative hospitals in Korea to promote customer convenience Stem cell global treatment available at over 50 partner hospitals overseas

October 2015

Completion of 1 GMP Center

May 2016

Ministry of Food and Drug

Safety GMP Survey

April 2019

Completion of 2 GMP Center

Can culture 6000Lot

cells per year

(500Lot per month)

Management system

based on GMP facility of the Ministry of Food and

Drug Safety

Atopic dermatitis

stem cell treatment clinical approval

(clinical phase 2 in progress)

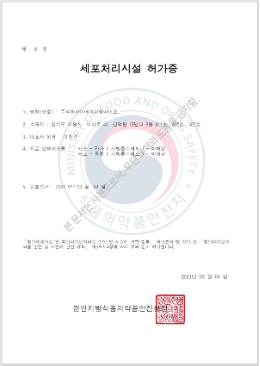

Acquired CPC(Cell Processing Center)

permission from the Ministry of Health,

Labor and Welfare of Japan

Acquired the 1st human cell etc

management business in Korea

Acquired CPC(Cell Processing Center)

for the 1st time in Korea

Clean Room

Airborne particulates are managed below the specified cleanliness

Maintain cleanliness to protect raw materials used in manufacturing space

Area or space designed to manage the environment such as temperature and humidity

Built-in incubator planned from the design stage

Biological Safety Cabinet (BSC)

Used in laboratories dealing with infectious substances such as pathogens

Basic safety equipment used to protect handling materials, experimenter's safety, and environment

It is classified into class1, class2, and class3 according to the type and speed of inflow and exhaust air in the equipment

CO2 incubator

Tissue culture thermostat equipped with the function of maintaining the gaseous environment with carbon dioxide added

Device for adjusting the pH of the culture medium

Supply of set CO2 and maintenance of temperature

Centrifuge

Purpose of dividing the homogenate into several parts using centrifugal force

Spins at high speed and separates materials according to particle size and density

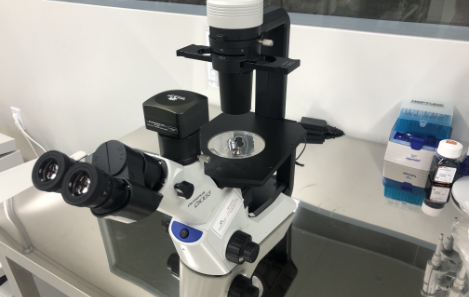

Inverted Microscope

Capture the image with an objective lens and refract it with a prism to observe it from the front eyepiece

The morphology and function of the proliferating cultured cells can be observed

Liquid nitrogen tank

It is used for long-term preservation of cells at cryogenic conditions.

It is liquefied nitrogen and exists as a liquid at -196 ° C under atmospheric pressure.

Air Handling Unit

A device that supplies outside air into the clean room

Heating coil, cooling coil, humidifier, air filter, blower unit

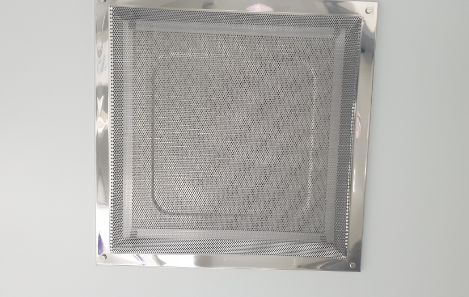

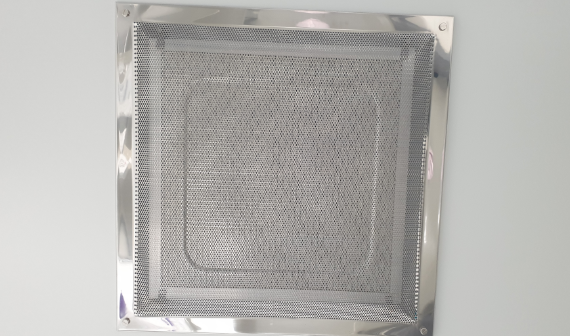

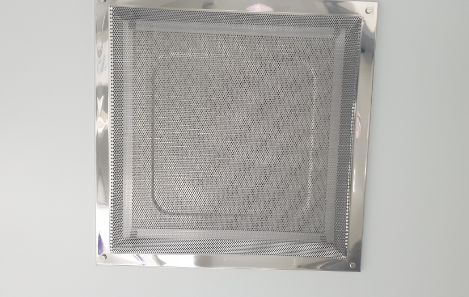

HEPA Filter

HEPA: High Efficiency Particulate Air (99.97%)

Air purification device developed to purify airborne particulates

For commercial use that requires an entirely clean air environment for safety